At antcivil, our range includes:

| Features | Benefits |

|---|---|

| Functional design | Allows easy attachment of spring hydrant, air valve or screwed outlet |

| Functional design | Allows easy attachment of spring hydrant, air valve or screwed outlet |

| Functional design | Allows easy attachment of spring hydrant, air valve or screwed outlet |

| Functional design | Allows easy attachment of spring hydrant, air valve or screwed outlet |

antcivil hydrant & air valve isolation valves are manufactured and independently third party certified to NZS4522 “Underground fire hydrants”

Accreditation body: Australian Certification Services – 30048

antcivil hydrant & air valve isolation valves are manufactured and independently third party certified to NZS4522 “Underground fire hydrants”

Accreditation body: Australian Certification Services – 30048

antcivil hydrant & air valve isolation valves are manufactured and independently third party certified to NZS4522 “Underground fire hydrants”

Accreditation body: Australian Certification Services – 30048

antcivil hydrant & air valve isolation valves are manufactured and independently third party certified to NZS4522 “Underground fire hydrants”

Accreditation body: Australian Certification Services – 30048

antcivil hydrant & air valve isolation valves are manufactured and independently third party certified to NZS4522 “Underground fire hydrants”

Accreditation body: Australian Certification Services – 30048

| Item | Part Name | Material |

|---|---|---|

| 1 | Table Data | Table Data |

| 2 | Table Data | Table Data |

| 3 | Table Data | Table Data |

| 4 | Table Data | Table Data |

| 5 | Table Data | Table Data |

| Specifications | Sym | Units | DN 80 | DN 100 |

|---|---|---|---|---|

| 1 | Table Data | Table Data | Table Data | Table Data |

| 2 | Table Data | Table Data | Table Data | Table Data |

| 3 | Table Data | Table Data | Table Data | Table Data |

| 4 | Table Data | Table Data | Table Data | Table Data |

| 5 | Table Data | Table Data | Table Data | Table Data |

antcivil hydrant & air valve isolation valves are manufactured and independently third party certified to NZS4522 “Underground fire hydrants”

Accreditation body: Australian Certification Services – 30048

| Property | Value & Unit |

|---|---|

| Ultimate tensile strength (Minimum) | 500MPa |

| Elongation (Minimum) | 7% |

| Density (Specific Gravity) | 7.1 |

| Property | Value & Unit |

|---|---|

| Ultimate tensile strength (Minimum) | 500MPa |

| Elongation (Minimum) | 7% |

| Density (Specific Gravity) | 7.1 |

antcivil hydrant & air valve isolation valves are manufactured and independently third party certified to NZS4522 “Underground fire hydrants”

Accreditation body: Australian Certification Services – 30048

antcivil hydrant & air valve isolation valves are manufactured and independently third party certified to NZS4522 “Underground fire hydrants”

Accreditation body: Australian Certification Services – 30048

WSAA-approved, stackable spindles provide flexible sizing solutions, ensuring reliable valve access, durability, and ease of installation for various applications.

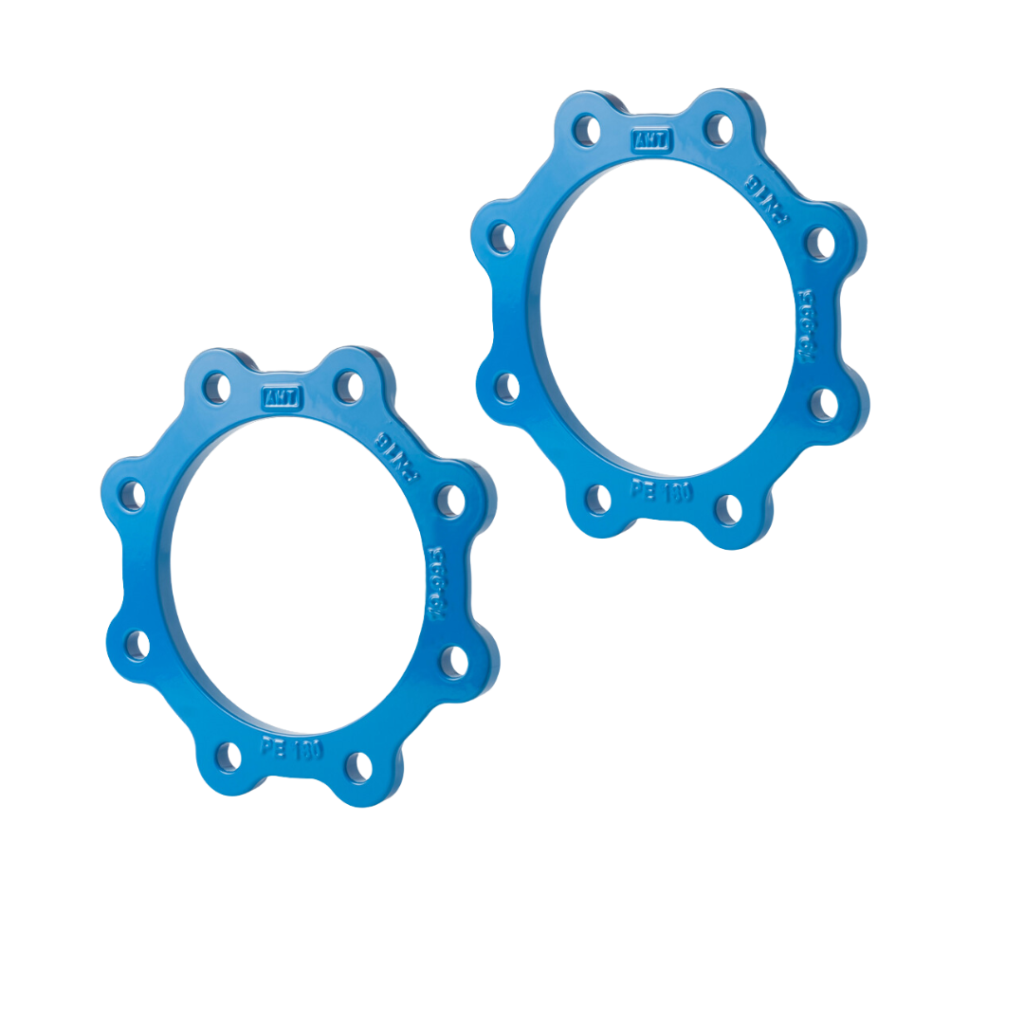

Heavy-duty ductile iron rings with a fusion-bonded epoxy coating, ensuring superior corrosion resistance and long-term durability for secure water infrastructure connections.

Ductile iron rings with a protective fusion-bonded epoxy coating, designed for enhanced durability and reliable performance in water infrastructure applications.